Pallet Forks: A Complete Guide (including 6 safety tips)

As a company, you want to be good at what you do. Usually, this means being efficient and profitable with your work.

To achieve efficiency, you need quality tools for the job.

For example, you could use a teetering five-gallon bucket to reach something on a high shelf. While this is doable, it's inefficient and dangerous - your chances of ending up with bruised pride or a twisted ankle greatly diminish if you get a ladder, which is the right tool for the job.

One piece of equipment that is easy to cut corners on is a pallet fork. Pallet forks are essential to manufacturing businesses, but a high-quality one can be an investment. However, when they bend, wear out quickly, or don't fit the job or machine, it causes numerous issues like,

- Employee frustration

- Time and material waste, and

- Safety concerns.

At Sidekick Attachments, we understand the need for efficiency and care deeply about quality products. This is why we build long-lasting, quality pallet forks specially designed for your machine and job!

In this article, we will cover all things pallet forks, including different kinds of pallet forks, uses and benefits, safety tips, and how to choose the right pallet fork for your machine.

Ready to learn more?

Let's begin!

What Is a Pallet Fork?

A pallet fork is a two-pronged piece of equipment designed to lift pallets (hence the name) and other heavy objects. It can attach to various machines, including tractors, forklifts, and skid loaders. Pallet forks are made from high-tensile forged steel with a standard length between 36 and 48 inches.

Pallet Fork Benefits & Uses

Pallet forks seem like a pretty simple product – so is a quality pallet fork worth the investment?

Let's examine some of the benefits of owning one!

Benefit #1 - Greater efficiency

Using a great pallet fork means more efficiency and less frustration. Not only does this save your company money, but it also gives your employees the tools they need to do their jobs well. When employees are happy, they are up to 20% more productive. It's an all-around win!

Benefit #2 - It's safer

Maintaining a safe workplace is incredibly important. A pallet fork allows employees to safely move large, heavy objects and loads with less risk of injury. However, a pallet fork needs to be used correctly to be safe.

Benefit #3 - Pallet forks are customizable.

Pallet forks can suit virtually any project, meaning they can be custom-designed to suit your requirements.

Benefit #4 - Pallet forks are super versatile.

Pallet forks can be attached to various machines, such as telehandlers, loaders, skid steers, and tractors, which means they can be used in many applications. The more uses you have for a tool, the more it profits you.

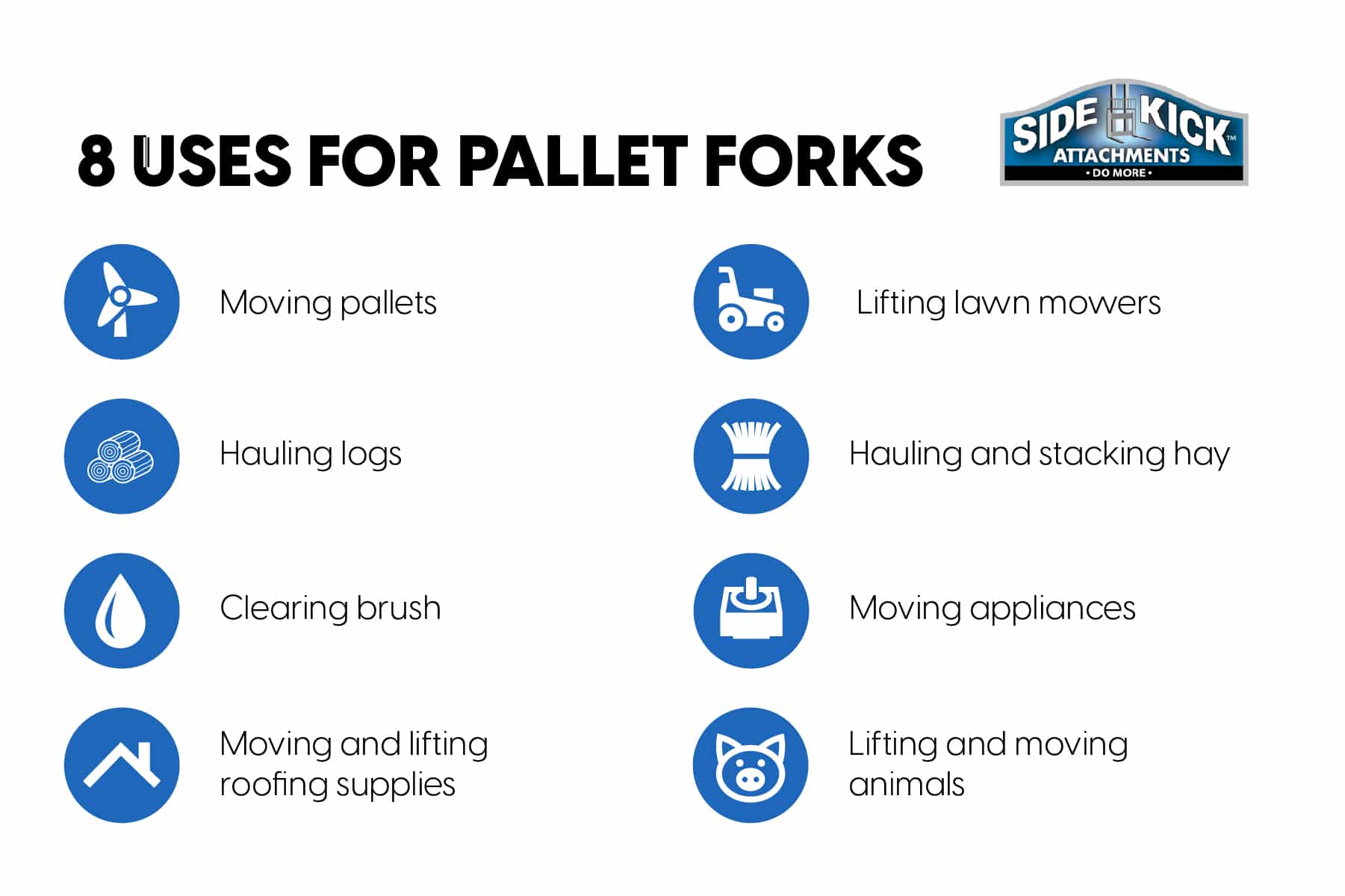

Not only are there many benefits to owning a pallet fork, but they also have a surprising number of uses!

Here are a few of them:

Use #1 - Moving pallets!

The number one use of a pallet fork!

Use #2 - Hauling logs

Pallet forks can be an excellent tool for moving and lifting logs for safer cutting.

Use #3 - Clearing brush

When clearing brush, it saves lots of time to pile brush right on the pallet fork to be easily hauled away.

Use #4 - Moving and lifting roofing supplies

Roofing supplies are heavy! A pallet fork can easily move and lift roofing supplies to get them where they need to be. It's also safer than hauling materials up and down ladders.

Use #5 - Lifting lawn mowers to be cleaned

Do you have a lawn care business? A pallet fork can lift a mower for easy and safe access for cleaning or maintenance.

Use #6 - Hauling and stacking hay

A pallet fork can reach high places, allowing you to stack bales more efficiently and quickly.

Use #7 - Moving appliances

Because of their weight, large appliances, like trash hoppers, can be challenging to move. It's also easy to damage them in the process. A pallet fork is an excellent option for moving appliances with ease.

Use #8 - Lifting and Moving Animals

Do you like to hunt? A pallet fork is an excellent tool for lifting a carcass for butchering!

Don't put yourself in a box when it comes to pallet forks! Their many uses only increase their value and make them a great tool for varied businesses like manufacturing companies, farms, warehouses, and roofing companies.

11 Types of Pallet Forks

There are various pallet forks, some designed for different machines and some with different features.

For example, pallet forks can be made for

- Tractors

- Skid steers

- Forklifts

Each of these forks is specially designed to fit the size and load capacity of the machine to which it attaches.

Pallet forks are also designed with various features and for many different tasks.

Let’s take a look at a few of them!

- Quick attach pallet fork: these forks are designed with only one attachment point. This makes it possible to attach and detach the forks quickly.

- Bolt-on pallet fork: these forks are bolted to the carriage and limit fork movement.

- Block fork: this type of fork includes multiple sets of tines, allowing for various kinds of pallets and blocks to be moved without needing to change forks.

- Lumber forks: These forks have fully tapered and polished tines, and they are specially designed to easily load and unload stacks of lumber.

- Shaft forks: these forks are made for pin-in carriages.

- Fork extensions: these forks fit over shorter ones, making it possible to move larger, bulkier loads.

- Inverted forks are designed to carry loads from the top rather than the bottom, and they are used in areas with low ceilings.

- Gypsum forks are specially designed with slide-in pads, which are used to move gypsum wallboard and similar fragile materials.

- Folding pallet forks fold to allow greater mobility in tight spaces.

- Spark retardant forks are designed to reduce the chances of sparks and are used in areas that contain flammable materials or chemicals.

- Stainless steel coated forks: these forks are used in areas where sanitation is a concern (e.g., handling food and beverages)

As you can see, pallet forks come in many shapes and sizes and are incredibly versatile!

If you have things to move, pallet forks are with investing in!

Choosing the Best Pallet Fork for You!

A quality, long-lasting pallet fork needs at least two components, quality craftsmanship, and correct fit. Here are a few things to look for when purchasing a pallet fork.

Value quality craftsmanship

Pallet forks are made from steel, but the steel quality can vary. A great fork will be made from high-quality forged steel and be reinforced in the heel. When forks aren't reinforced here, normal wear and tear cause them to wear out much more quickly than they would otherwise. With our Optimal Heel design, Sidekick Attachments reinforce the heel of the forks to mitigate the effects of regular use and extend the life of the forks.

Make sure the manufacturer is meeting ITA, ANSI, ISO, ASME, and EMI standards

These standards ensure the quality and performance of the pallet fork. They also ensure that the pallet fork will work well with other pieces of equipment.

Ask the manufacturer about their inspection process

A pallet fork should go through numerous inspections before being ready for use. For example, 100% hardness check, 100% magnetic particle non-destructive testing, 100% hanger spacing inspection, and 100% tip alignment/straightening inspection.

Check the rating stamped on the fork

Each fork should be stamped with a load center rating. A 24-inch load center rating is generally the safest choice since most pallets are 48 inches square. However, it is most important that the load center matches your equipment recommendations.

What's the job?

It's important to think of what job you need to accomplish. If you need to lift blocks or stones, you'll want to purchase a heavy-duty fork. Hauling lumber? Then you'll want to purchase lumber forks that are specially polished and tapered for handling lumber. Remember, different applications require different things from your fork. Make sure you are buying forks designed for the job!

Find the correct fit

It is very important that the forks you use are the correct fit for your machine. For example, light-medium duty forks are generally better suited for small skid steers. Ensure that the load center of the forks matches what is recommended for your machine and that its operating capacity is less than its tipping point. An incorrect fit may create tension points on the fork or machine and cause safety issues.

Ask a professional!

One of the best things you can do is ask a professional. At Sidekick Attachments, our team has lots of experience and would love to help you find the pallet forks that are right for you!

Now that you know how to find the right pallet forks for you, how should you operate them safely?

Great question! Here are a few useful tips for using a pallet fork safely.

Safety Tips

1. Make sure your load is stable

Use ballasting if needed and make sure the load is securely fastened and balanced on the forks so it won’t shift suddenly.

2. Use the whole pallet fork

This is related to making sure the load is balanced but is a common mistake particularly when you’re in a hurry. A load should never be balanced on one tine or on the front of the tines. Rather, make sure your load is balanced toward the back of your forks.

3. Follow directions for use and load limits

Make sure to follow directions for use and respect load limits. Incorrect use and overloading are very risky and may cause serious accidents. I remember as a child watching my father move a load of stone that was over the load limit. He did not get far before the machine tipped forward - directly in front of me. Thankfully, he wasn’t moving quickly and so, other than being badly shaken, we were both unhurt.

4. Don’t move too quickly!

Never move quickly with a loaded pallet fork. This increases the risks of accidents as well as their severity.

5. Don’t use the fork to grab, pry, or dig

Use pallet forks for what they were designed to do - lift and move loads. Never try to pry, grab, or dig with a pallet fork.

6. Don't jerry rig forks

It's easy to think that you might add a ball hitch to a fork or alter them in a way to get another job done. Don't do it! This isn't approved practice and you may end up injuring yourself or others.

7. Do regular maintenance on the fork and machine

Regularly check the tire pressure of your machine and the wear on your pallet fork.

You should never skimp on safety! Even though it may seem like the easiest option at the moment, it’s never worth the risk of injury or death and doesn’t pay in the long run!

What Makes Sidekick Attachments' Pallet Forks Unique?

There are lots of companies who sell pallet forks, so what makes Sidekick Attachments' pallet forks unique?

First, our Optimal Heel design on our standard forks mitigated the regular wear and tear of everyday use. This means your pallet fork will last longer!

Second, we work with you to make sure the forks are properly sized for your machine. This includes customizable sizing!

And finally, we offer a 15-day satisfaction guarantee on all of our products and a 90-day warranty. If something goes wrong with the product, we’ll fix it!

Conclusion

Why are pallet forks so important?

Pallet forks are a vital part of many businesses. Great forks result in more efficiency and greater profits. They also help create a safer work environment.

At Sidekick Attachments, we believe every company deserves a quality pallet fork that fits their needs. Getting one is simple!

- Browse our website to find the right forks for you!

- Order your product! We offer shipping within 2 business days for many of our products!

- Enjoy the results of a quality pallet fork!

You may be also interested in our other products, which include forklift extensions and forklift trailer movers.

We look forward to hearing from you soon!