Forklift Trailer Movers Explained: Choosing the Right Model for Your Operations

What if you could eliminate the single biggest bottleneck in your material handling process? Are you sick of wasted time, strained backs, and the constant threat of costly accidents? What if you could dramatically boost safety and efficiency with one strategic investment? You’re not dreaming of a miracle, you’re seeking efficiency.

Now, imagine a solution that elevates your productivity, ensures safety, and simplifies your processes. We’re talking about the forklift trailer mover.

Choosing the right forklift trailer mover can feel overwhelming. You need something reliable, efficient, and safe – but with so many options, how do you choose? We understand the pressure of making the right decision for your business. You deserve a smooth, efficient operation, free from the worry of equipment failures.

Understanding this tool is essential for making informed decisions that suit your operational needs. You deserve equipment that maximizes performance without compromising on safety and quality. At Sidekick Attachments, we bring years of expertise in designing high-quality, efficient, and safe forklift attachments.

In this blog, we guide you through the essential factors to consider when selecting the right forklift trailer mover for your business. We discuss load capacity requirements, maneuverability requirements, compatibility issues, and features to look for.

What Is a Forklift Trailer Mover?

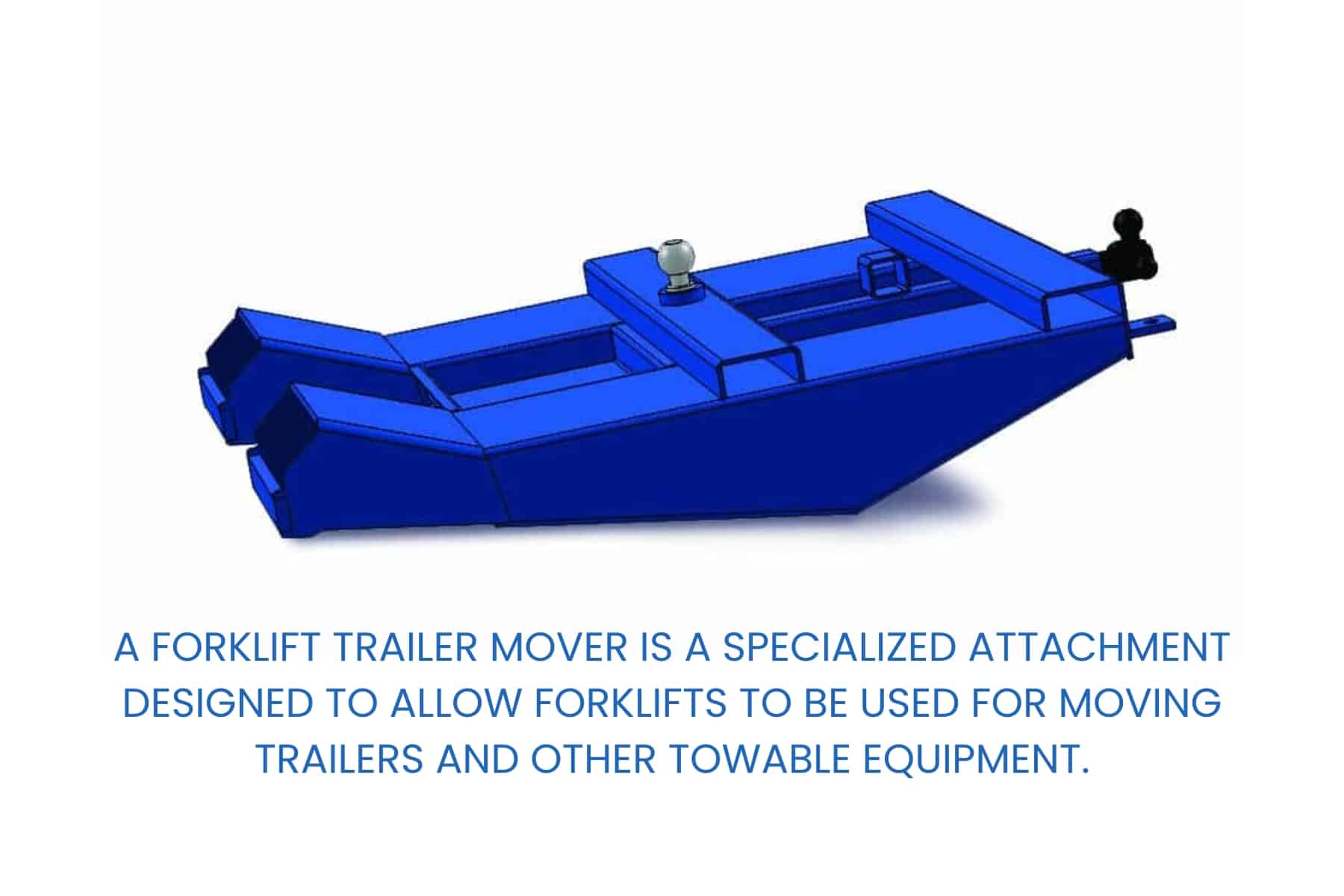

A forklift trailer mover is a specialized attachment designed to allow forklifts to be used for moving trailers and other towable equipment.

This attachment connects to the forklift's forks and allows operators to move trailers without needing a full-sized truck or tractor. It’s especially useful in warehouses, manufacturing plants, and distribution centers where space is limited, and maneuverability is crucial.

Here's a breakdown:

- Function:

- These attachments typically feature a hitch receiver (like a standard vehicle hitch) that allows the forklift to connect to a trailer.

- They can come in various designs, accommodating different types of hitches, including ball hitches, pintle hitches, and even gooseneck or fifth-wheel setups in some cases.

- The purpose is to provide a safe and efficient way to maneuver trailers in confined spaces, such as warehouses, loading docks, or storage yards, where a full-sized vehicle might struggle.

- Variations:

- There are simple hitch adapters that slide onto the forklift's forks, and there are more robust, purpose-built trailer movers with integrated hitch systems.

- Some models are designed for heavy-duty applications, capable of moving very large and heavy trailers.

- Also some models are designed for hands free connecting and disconnecting from the trailer.

With a forklift trailer mover, operators can position trailers with greater precision, improving workflow efficiency and safety. These attachments come in various designs, allowing them to accommodate different types of trailers. By using a forklift trailer mover, businesses can reduce the need for additional equipment, streamline material handling processes, and enhance overall productivity.

Understanding Load Capacity Requirements

When choosing a forklift trailer mover, load capacity should always be the first consideration. Different trailer movers are designed to handle varying weights. Selecting one that can accommodate your typical loads is key to preventing equipment failure and ensuring the safety of your operations.

When choosing a forklift trailer mover, load capacity should always be the first consideration. Different trailer movers are designed to handle varying weights. Selecting one that can accommodate your typical loads is key to preventing equipment failure and ensuring the safety of your operations.

Maneuverability and Space Constraints

Next, consider the space where you’ll be operating. Will the forklift and trailer mover have enough room to maneuver? In tight warehouse or factory spaces, maneuverability is key. Consider the layout and measurements of your facility to determine how much space you have for operations.

Some forklift trailer mover designs are more compact and easier to maneuver in confined areas. These designs often feature smaller turning radii and improved visibility. Think about the dimensions of your workspace, including aisle widths, turning spaces, and any obstacles. You’ll want a mover that can efficiently navigate your facility without hindering workflow or increasing the risk of collisions.

High maneuverability allows for smoother operations and better handling in tight spaces. This means less risk of accidental impacts or damage to both the equipment and the goods being transported. Choose a trailer mover that can efficiently navigate your operational environment. This translates to shorter movement times and increased productivity.

To learn more about improving efficiency with the right attachments, read our post on “6 Insanely Useful Forklift Attachments to Boost Efficiency.”

Compatibility with Your Forklift

Once you have a clear picture of load capacity and maneuverability, the next step is ensuring compatibility with your current forklift. This involves checking the hitch connection and power requirements of both the forklift and the trailer mover. Consider factors such as the type of forks, the attachment mechanism, and the overall weight capacity of your forklift.

Using an incompatible attachment can lead to operational issues, damage to your forklift, or even accidents. You need to ensure the hitch mechanism on the mover fits perfectly with your forklift’s hitch type.

Power compatibility, especially in electric forklifts, is another critical factor. Make sure to double-check the specifications of both your forklift and any potential mover. Misalignment in these areas can lead to operational inefficiencies and additional costs for adapter equipment or even new forklifts.

A harmonized operation between your forklift and trailer mover extends the life cycle of your equipment and drastically reduces potential downtimes.

For a more detailed exploration of compatibility issues and finding the perfect fit for your equipment, check out “The Ultimate Guide to Forklift Extensions (and other forklift attachments).”

Features to Look for in a Forklift Trailer Mover

Finally, look for specific features that distinguish one trailer mover from another. Check for automated systems, ergonomic controls, and advanced hitch functionality. These attributes enhance the efficiency and safety of your operations.

Key Features to Consider

- Ease of Attachment and Detachment:

- A simple, intuitive system saves valuable time and reduces the risk of errors during operation.

- Our forklift trailer movers can be operated hands-free; you don’t even need to get off your forklift. No chains, pins, or extra gadgets means no wasted time hooking up the attachment.

- Ergonomic Design:

- This enhances operator ease and reduces fatigue, leading to longer shift capabilities and error reduction.

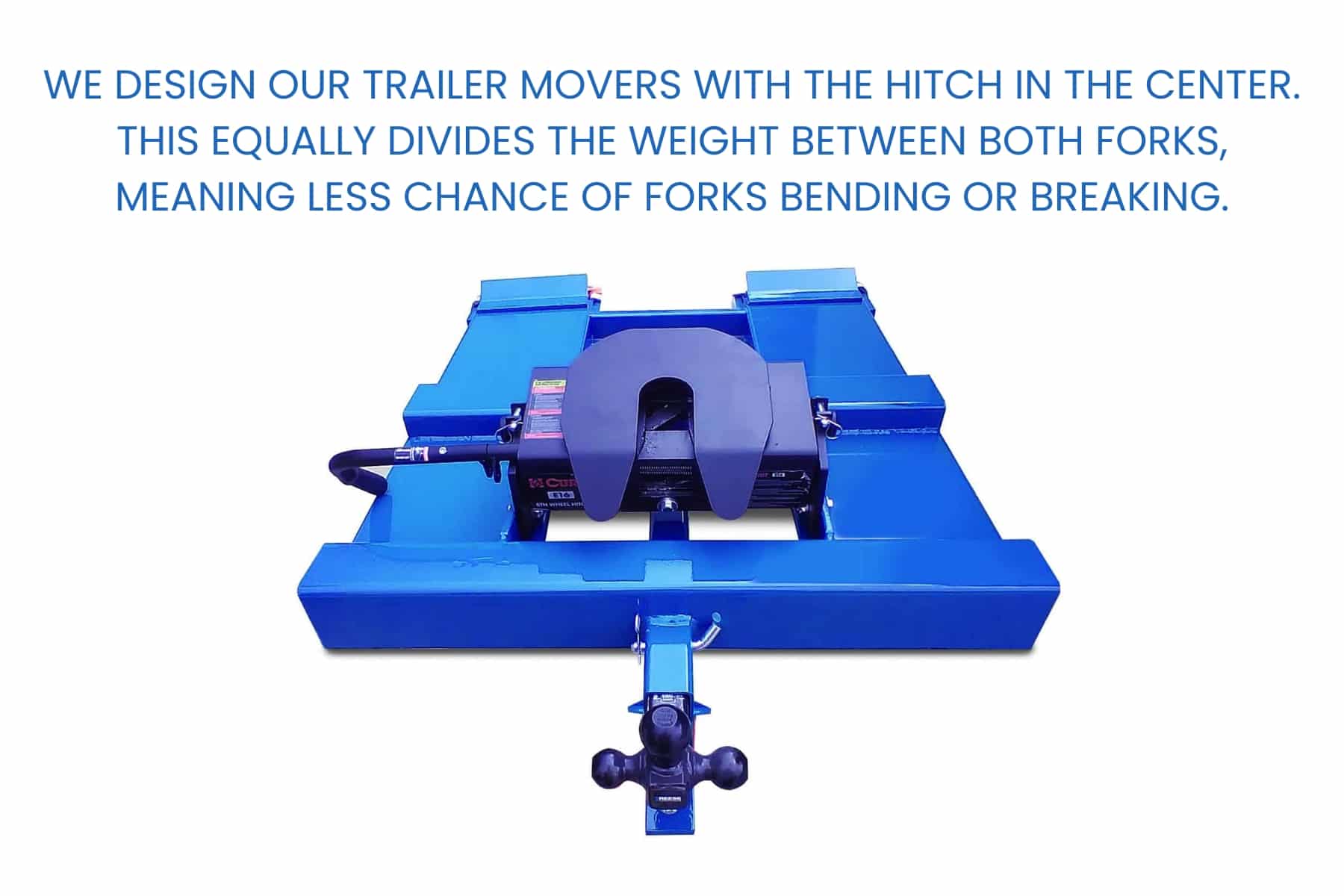

- We design our trailer movers with the hitch in the center. This equally divides the weight between both forks, meaning less chance of forks bending or breaking.

This also allows for smoother and more stable trailer control for safer movement.

- Versatility:

- Ensure the mover can handle various trailer types and sizes, providing operational flexibility.

- Our trailer movers are designed to move standard trailers (both with ball and pin hitches), gooseneck trailers, and fifth-wheel trailers. No extra trucks or tractors are necessary.

Don’t underestimate the importance of these features. Investing in high-quality attachments pushes safety and efficiency boundaries and adds long-term value. For more on extending your equipment’s functionality, explore our guide on Pallet Forks: A Complete Guide.

In conclusion, understanding the integral factors in selecting a forklift trailer mover is paramount for any business looking to maximize operational efficiency. From assessing load requirements and space constraints to ensuring compatibility and valuable features, these choices lay the foundation for streamlined, productive processes.

Investing in a quality forklift trailer mover may seem expensive upfront, but it provides long-term benefits. A high-quality, well-maintained mover minimizes downtime and reduces the need for frequent repairs or replacements. This translates into significant cost savings in the long run. A high-quality mover pays for itself over time through efficiency and longevity.

Empower Your Operations

Now that you have this comprehensive understanding, it’s time to transform your operational approach. Choosing the right forklift trailer mover is vital for efficiency and safety. By considering load capacity, maneuverability, compatibility, key features, and long-term costs, you can make an informed decision.

At Sidekick Attachments, we’re committed to providing high-quality, efficient, and safe forklift attachments. We invest heavily in research and development, constantly striving to improve our products and design innovative solutions for our customers. Our dedication to innovation allows us to develop cutting-edge solutions, which translate directly to improvements in efficiency and safety.

Your business deserves the best, and with the right forklift trailer mover, you can achieve more than you ever imagined.

Contact us today to find the perfect solution for your business. We look forward to hearing from you!